OEM Supply Mining Rock Extension Rod - R22 R25 R28 R32 R35 R38 T38 T45 T51 GT60 ST58 ST68 Threaded Rock Drill Rods for Mining Tunnelling Blasting – Gimarpol

OEM Supply Mining Rock Extension Rod - R22 R25 R28 R32 R35 R38 T38 T45 T51 GT60 ST58 ST68 Threaded Rock Drill Rods for Mining Tunnelling Blasting – Gimarpol Detail:

Product Name: Drill Rod

ltem No.:B19 B22

Color: Black,Blue, Red or as your request

Size: As your request

Advantage: Domestic famous brand, high quality,

strictly inspection and test, good after-sales service.

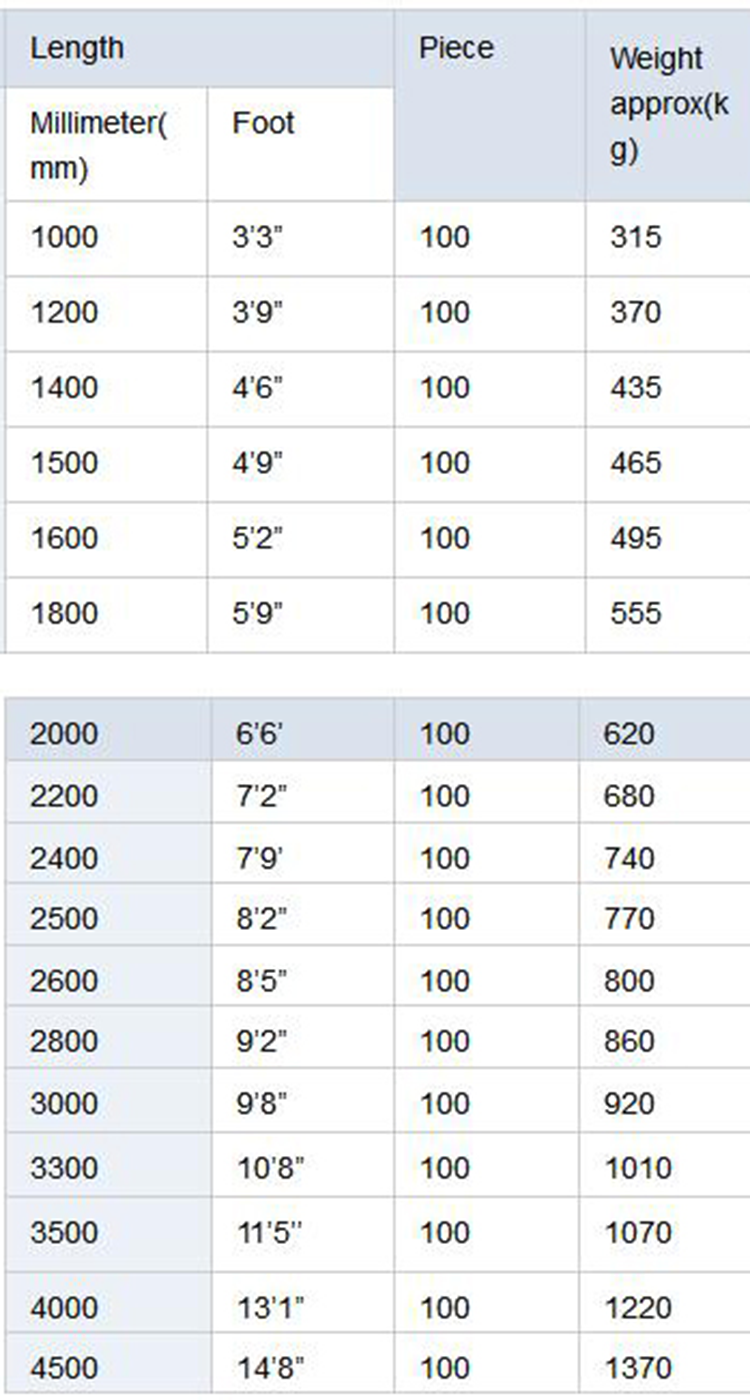

Effective Lenath: 1000-4500 MM

Features: Ensure good drilling life by using superior tungsten carbide.

Stale and mature welding technology ensure good quality of rods.

lntegrate heat treatment ensure rod quality.

Package: Wooden case or as your request

MOQ: 100OPCS

Delivery Time: 3 davs after confirmed the payment

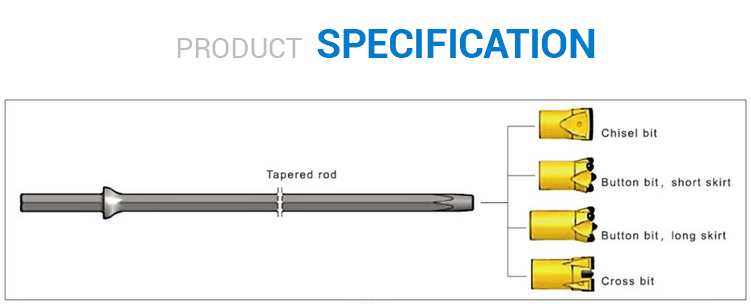

Gimarpol’s Tapered Drill Rod with a hexagonal chuck section to provide leverage for the rotation chuck bushing. It usually has a forged collar to maintain the proper shank striking face position in the rock drill, and a tapered drill bit in the end. Tapered steel lengths are measured from the collar to the bit end. Holes are usually drilled in 0.6 m increments to accommodate the air leg feed length. The drilled steel is extracted and followed with a slightly smaller diameter rock drill bit on the next steel length in the sequence.

Drill rods are divided into three categories: kelly rods, drill rods and heavy drill rods. The connection sequence is kelly (1) + drill pipe (n, determined by the depth of the well) + weighted drill pipe (n, determined by the design of the drill tool assembly).

Kelly

The kelly is located at the uppermost end of the drill string, and there are two types of square and hexagonal [3].

effect

①When drilling, the kelly rod is matched with the core and the turntable to transfer the ground rotation torque to the drill rod to drive the drill string and the drill bit to rotate;

② Bearing the full weight of the drill string;

③ Channel for circulation of drilling fluid.

structure

The kelly rod is composed of upper and lower joints and a pipe body. The pipe body has two structures: tetragonal or hexagonal (mostly oil drilling is tetragonal); the upper joint is a left-handed female thread (reverse buckle), which is connected to the faucet, and the left-handed female thread prevents undercutting during rotation; the lower joint It is a right-handed male thread, which is connected with the drill pipe. When working, the upper end of the kelly rod is always above the surface of the turntable, and the lower part is below the surface of the turntable.

Drill pipe

effect

The drill pipe is the basic part of the drill string. Its main function is to transmit torque and transport drilling fluid, and to deepen the borehole continuously by the gradual lengthening of the drill pipe. Therefore, drill pipe occupies a very important position in oil drilling.

structure

Drill pipe structure The drill pipe is made of seamless steel pipe with a wall thickness of 9-11mm. The pipe body and the joint are butt welded together by friction welding.

Heavy drill pipe

Heavy drill pipe is similar to petroleum drill pipe, but also a hollow steel column with a length of about 10 meters. However, the weight of a single rod is heavier than that of oil drill pipes, and the wall thickness is 2 to 3 times that of drill rods. The heavier drill rod is connected between the drill rod and the drill collar to prevent fatigue damage due to the change of the drill string cross section. It can also replace part of the role of the drill collar, but its suspension is simple, and the operation of starting and running is convenient, which can save the time of starting and running.

There are two standard steel hex diameters – 22mm or 25mm. And Our tapered bit and rods come in a variety of taper angles( 7 degree, 11 degree, 12 degree)

Gimarpol’s Tapered rods are available with high-frequency or fully carbonized heat treatments.

Taper Angle:7°,11°,12°

Socket Diameter:H19,H22,H25 MM

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. High-quality is our life. Consumer need to have is our God for OEM Supply Mining Rock Extension Rod - R22 R25 R28 R32 R35 R38 T38 T45 T51 GT60 ST58 ST68 Threaded Rock Drill Rods for Mining Tunnelling Blasting – Gimarpol , The product will supply to all over the world, such as: Uganda, Namibia, Bolivia, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we have gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.